On the Cutting Edge

March 2007

By John Brumm

Photograph by Joseph Byrd

||

|---|

|

|

No piece of gear defines scuba's early black-and-white era better than the big, bayonet-length dive knife. Back in the day, no self-respecting diver would dare enter the water without a trusty (and often rusty) weapon of mass destruction strapped to his leg. But just as the analog dive watch gave way to the dive computer, and the j-valve was replaced by the submersible pressure gauge, the old-school dive sword has been upstaged by a better alternative.

The new breed of dive knives tends to be smaller, which makes them easier to mount and stow; they have innovative blade designs which make them better suited to their true task of cutting through rope and fishing line (not throats and air hoses); and they're made of rust- and corrosion-resistant metals so they last longer and hold an edge better.

Making the Cut

The 11 models profiled here range from small emergency folding knives you can stash in a BC pocket, to traditional fixed-blade knives designed to be worn on a webbed belt or, if you're a traditionalist, strapped to your leg.

We put them all to the test to see how well they cut a variety of materials. Then we subjected them to our "rust test," an extended period of wet neglect in a saltwater environment to see how well they resist rust and corrosion.

For the cutting tests, we tried each blade in out-of-the-box condition on five different materials that today's divers are likely to face: 30-pound monofilament fishing line; 1/8-inch general-purpose Dacron line; 3/8-inch polypropylene line; 1/2-inch three-strand nylon anchor line; and 5/16-inch Vectran--a single-braid, low-stretch marine line so tough that it's used as a substitute for wire rigging. We discovered that the cutting efficiency of each knife depends largely on what's being cut. When attacking monofilament and Dacron line, virtually all knives get the job done. It's when you start sawing into the larger three-strand ropes and braids that you start seeing how different blade designs--not to mention cutting techniques--come into play (see: "The Cutting Test").

We tested for rust resistance by soaking the knives in salt water twice a day for 15 consecutive days. After each dunking, the knives were set out to dry while still in their sheaths. To our surprise, none of these knives showed much rust or corrosion at all. Most rust that appeared could be wiped off with a freshwater rinse and a brisk rubdown with a terry cloth towel. In spots where rust persisted, some light scraping with a razor blade took care of the problem. This clearly illustrates that any of these knives can be kept totally rust- and corrosion-free with just a little TLC (see: "Clean Cuts: Dive Knife Maintenance Tips").

Fixed Knives

OMS: Ti Knife

|||

|---|---|

|

|

Compact, lightweight and housed in an effective sheath, this knife brings a three-inch, nonmagnetic titanium blade to bear when it's time to go to work. The blade features a blunt tip for prying and a combination of plain and serrated cutting edges. The sharp serrated points, interspersed with a plain edge, were able to hack through most of our cutting jobs, but they tended to snag on ropes and woven fibers more than the other knives in this test group. It aced the rust test, of course, as titanium simply doesn't fall victim to corrosion. Another plus: The knife comes in a handy delrin sheath. It can be threaded onto two-inch webbing or clipped to virtually any BC strap, and it holds the blade securely in place while also allowing easy one-handed access. The high-vis orange handle is textured for a firm grip and provides a good blade guard to keep fingers from slipping.

SCUBAPRO: Mako

|||

|---|---|

|

|

The sleek new Mako is made from a single piece of either 304 stainless steel or titanium, and both versions give you a number of cutting surfaces to work with. There's a primary serrated/plain edge, a sharpened tanto tip that lets you both pry and slice, and a line-cutting notch for monofilament. We tested the 304 stainless version, which resisted rust buildup like a champ, but didn't hold an edge as well as other knives in this test (try the titanium version if you need a sharper blade). On the plus side, a composite rubber handle and blade guard provide a solid grip without the worry of fingers slipping into harm's way. The blade stows securely in a plastic sheath with a spring-loaded release button that lets you pull and replace the knife with one hand. The sheath also comes with two narrow straps for mounting on your calf or forearm. The straps use unique buckles to make it easy to mount or remove the sheath, and they are easily adjustable. Bonus: On the end of the handle there's a bottle opener, making this a tool you'll want to keep handy topside, too. Safety tip: Scubapro stresses the bottle opener should be used only when the knife is secured in the sheath. Good advice.

SPYDERCO: Caspian2 Salt

|||

|---|---|

|

|

This innovative cutter is made from a seven-inch piece of H1 stainless steel, which uses nitrogen in place of carbon in its steel matrix. According to Spyderco, this allows for superior rust resistance plus enables the three-inch blade to hold a super-sharp edge. The unit we tested was a prototype, and its cutting edge was half serrated, half plain. There was also a line cutter and a blunt tip for prying. But what really helped the knife's efficiency was the handle. First off, it has a cutout to reduce overall weight. What's left is overlaid with nonslip fiberglass-reinforced nylon. The key to the design is the index finger hole and textured metal spine where blade and handle meet. Put your index finger through the hole, and your thumb on the textured spine, and you've got yourself a rock-solid grip that radically increases leverage for sawing through all kinds of nasty stuff. The sheath wasn't available at press time, but Spyderco says it will feature a button release that lines up with the index finger hole for increased security.

TUSA: FK-850 X-Pert

|||

|---|---|

|

|

The full-sized FK-850 is one of the best all-around knives in this group as every available centimeter of its 420 stainless-steel blade is designed for cutting. The upper blade edge is divided between line-cutting notch, serrated edge and a short length of plain edge. The lower blade is a seriously sharp plain edge and the stiletto point is downright lethal. The plain edge proved to be the most effective choice, able to slice through half-inch anchor line and even hi-tech Vectran like butter. But its wavy-style serrated edge was almost as efficient. The blade is balanced by a contoured handle with a blade guard that's both comfortable and safe. The plastic sheath offers a push-button release and positive-click security system so you know it's not going anywhere. The knife is really too big to be strapped anywhere except on the leg, but it uses a unique buckle system that lets you unhook the sheath without unthreading the straps. Even better, squeeze buckles allow for hassle-free adjustment.

UNDERWATER KINETICS: Remora Ti

|||

|---|---|

|

|

This is a small emergency knife that comes with sheath attachments that enable you to mount it either on your BC, on a hose, or threaded onto a one- or two-inch web strap. The knife/sheath combo is only seven inches long and is very low-profile, so it stays tucked out of the way until needed. Just don't underestimate its cutting power. Its wavy-style serrated edge was able to saw through the thicker materials more easily than many of its larger competitors. The knife offers one-handed accessibility and a noncorrosive titanium blade with a basic serrated edge for sawing and a blunt tip for prying. There is no blade guard to speak of, but the handle offers a pair of molded shoulders to rest your thumb and index finger on, and a flat upper blade edge that you can bear down on with your thumb when cutting into something stubborn. The sheath doesn't have a push-button release, but the knife stows with a positive click providing a pretty secure fit.

UNDERWATER KINETICS: Blue Tang Ti Drop Point

|||

|---|---|

|

|

While the Remora is a compact BC knife, the Blue Tang is a traditional full-sized cutter that conjures up visions of Jim Bowie. The ultra-comfortable, contoured handle provides an excellent grip as well as a very efficient blade guard to prevent finger slips. The blade itself is made of lightweight, noncorrosive titanium and measures a full five inches-- enough room for a classic drop point, generous plain and serrated edges, and a line-cutting notch. The Blue Tang is a serious cutting tool, with one of the most efficient serrated sawing edges in this review, and an even meaner plain edge that seemed to cut better as the material got tougher. The knife locks securely into a composite sheath fitted with two narrow straps for lashing to your leg. The sheath also provides a one-hand release when you press both tabs flanking the handle. And if you're meticulous about maintaining your gear, you'll appreciate that the Blue Tang comes apart without tools for cleaning. It's also available with a blunt tip.

XS SCUBA: Fogcutter X Recon Knife

|||

|---|---|

|

|

The biggest knife in this group, the Recon measures over 12 inches overall, and sports a six-inch, all-black, chromate-finished 420 stainless-steel blade. The Recon actually provides two cutting functions. First and foremost, it's a traditional knife with long serrated and plain edges, a line-cutting notch and a pointed tip. But it also works as cutting shears. How? Half the blade and the handle split apart like a multi-tool to produce a relatively efficient shears-type cutter. In knife mode, the blade is also pretty efficient, although it tended to jam when sawing through thicker ropes with the serrated edge (always at the point where the cutting shears portion of the serrated edge butts against the blade portion). Also, in shear mode watch out for palm-pinching if you're not wearing gloves. As a knife, the Recon features a comfortable handle and a large blade guard that locks into the sheath for optimum security.

Folding Knives

SPYDERCO: Salt 1 (yellow) & Tasman Salt (black)

|||

|---|---|

|

|

The Salt 1 (shown in yellow) and the Tasman Salt (shown in black) use the same four-inch fiberglass-reinforced nylon handle with reversible titanium belt clip if you don't want to stow it in your BC pocket. Both feature the distinctive Spyderco round hole in the blade that makes it easy to open and close the blade with one hand, and both use a lever dent that locks the blade in an open position to prevent it from folding onto your fingers when you least expect it. Finally, both knives feature H1 stainless-steel blades.

Where the two knives differ is in the shape of their serrated edges. The Salt I has more of a convex cutting edge, while the Tasman Salt uses a curved "Hawkbill" blade. The Salt 1 blade is effective at both loop cuts and sawing against relatively flat surfaces. The Tasman blade has too much curve for standard sawing on flat surfaces, but excels in loop cuts.

SPYDERCO: Pacific Salt (black) & Atlantic Salt (yellow)

|||

|---|---|

|

|

Larger versions of the Salt 1 and Tasman Salt, these two folding knives come with all the standard Spyderco features, including H1 stainless-steel blades, Spyderco round holes for one-handed opening and closing, and lever dents to lock the blades open when in use. The Pacific Salt, with a slightly longer handle, uses a very efficient plain-edge blade (also available in a serrated version) with pointed tip that proved to be one of the best cutters in this review, regardless of knife style. The Atlantic Salt uses a serrated blade (also available in a plain edge version) with a more rounded tip, which is also very efficient. Both knives have textured fiberglass-reinforced nylon handles with belt clips and holes for lanyards. All internal steel parts are treated to make them impervious to rust, pitting and salt.

What To Look For In A Dive Knife

||

|---|

|

|

Efficient Cutting Edges. Most models come with either a plain edge, a serrated edge, or a combination of both. A plain edge is most effective at slicing-type cuts. If the cutting edge has a curve to it, referred to as "belly," it slices even better.

A serrated edge (top) is great for sawing-type cuts. Some serrated edges are pointy with sharp angles, others have a more wavy shape to their serrations. Wavy serrations (bottom) tend to cut material like heavy three-strand line more efficiently because the more rounded teeth run smoothly over the fibers, while the more pointy teeth have a tendency to get snagged.

Some blades offer both a serrated and a plain edge on the same cutting plane. Other knives separate their cutting edges; for example, the top edge is serrated, the lower edge is plain. This is a more functional design, because each edge type runs the entire length of the blade, thereby maximizing your cutting action.

Many blades also include a line-cutting notch (A). These are handy for snapping fishing line. However, a good plain or serrated edge will take care of monofilament just as efficiently.

||

|---|

|

|

A Functional Tip. Dive knives tend to come with one of three blade tips: a blunt tip, a pointed tip or a tanto tip.

The blunt tip (D) prevents you from accidentally stabbing yourself when returning the blade to its sheath. It also lets you use the knife as a pry tool without worrying about breaking the tip.

Pointed tips (B)--from stiletto to drop point styles--are not so good for prying, but they can make the difference between success and failure when you have to get a cut started by stabbing into a nasty rope knot. But be careful with a pointed tip; you can jab yourself or your BC bladder if you don't pay attention when sheathing it.

A tanto tip (C) is a bit of a hybrid. It's blunt, but with about a 70-degree angle to it and a sharp edge, similar to the edge on a chisel. You can do a little prying with less chance of snapping the tip, yet you also have that additional sharp edge if you need to do some cutting in tight spaces.

Blade Material. Most dive knives, and all knives in this review, feature blades made of either 304, 420 or H1 stainless steel, or titanium.

Softer 304 stainless steel offers excellent corrosion resistance, but it doesn't hold an edge as well as, say, 420 stainless, which does hold a sharp edge but rusts faster. H1 stainless is a special composite exclusive to Spyderco knives. It uses nitrogen in place of carbon in its steel matrix, resulting in a blade that's high in corrosion resistance while still being able to hold a very sharp edge.

And then there's titanium, the Superman of blade materials. It's harder than stainless yet lighter. You won't find better corrosion resistance, and the blade will hold a sharp edge for a long, long time.

A Good Handle. Regardless of the size of the knife, you want as much handle as possible to enable you to maintain a secure grip and full control of the blade. Good handles have textured surfaces or use special nonskid composites to provide a no-slip grip.

||

|---|

|

|

An Effective Blade Guard. (top) The design of the space between handle and blade is critical when it comes to a knife's efficiency as well as your safety. A metal or composite ridge or guard will keep your fingers from slipping forward onto the blade when you're bearing down on a cut. The best guards have a bit of a hook on the bottom side to catch your forefinger, and a thumb rest on the top.

A Place for a Lanyard. (bottom) Underwater, wearing gloves, in a stressful situation it's just too easy to drop the knife. Handles that feature a hole at their base for stringing a lanyard will radically increase the chances of the knife staying with you.

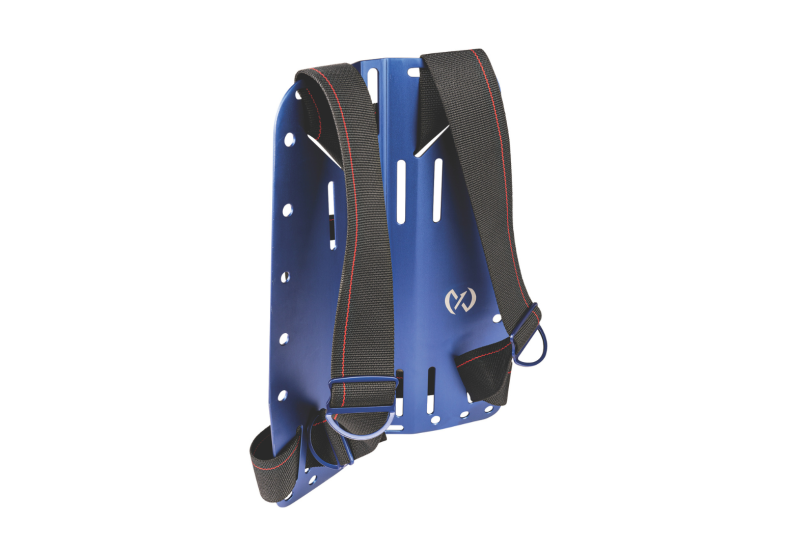

A Good Sheath with multiple mounting options. Where do you want to mount your knife? Some of the larger models come with double straps for lashing to your leg, just like in the old days. But sometimes you want to thread it onto your weightbelt or some other length of webbing. Some sheaths come set up to do this. Others can be modified for web threading. Still others come with accessories that let you mount the sheath on a console hose or a BC pocket flap.

A sheath should enable you to release and draw your knife with one hand. Also, when you return the knife to the sheath, it should engage positively with a "click," ensuring the knife stays where it belongs.

Folding Knives

Folding knives are handy because they don't require a sheath, and they stow easily, either in a BC pocket or on a belt via a flexible clip. Like fixed-blade knives, folding knives should have textured grips so that they're easy to hold onto, and places for attaching a lanyard. Finally, a good folding knife lets you deploy the blade using one hand. It will also lock in the open position so the blade can't collapse on your fingers.

The Cutting Test

||

|---|

|

|

For the cutting tests, we tried each blade on a collection of the stuff today's divers might face under water. With the blades at their out-of-the-box sharpest condition, we did damage to the following materials using two cutting methods:

Loop Cut. After forming a loop with the line, we held the base of the loop in one hand, while with the other we took the knife blade and attacked the loop using an upward cutting motion.

Saw Cut. A length of line was stretched over a block of wood. Laying each knife edge on the line, we used a sawing motion to sever the line.

Here are the results.

The Material: 30-pound monofilament fishing line. [1]

Best cutting technique: Use a line-cutting notch or plain edge. Hook the line in the notch or along the plain edge, apply some tension, then give it a quick snap.

Best tool for the job: All knives in this group worked equally well.

The Material: 1/8-inch general-purpose Dacron line. [2]

Best cutting technique: A single swipe of a sharp plain edge through a loop works best.

Best tool for the job: All knives in this review worked equally well.

The Material: 3/8-inch three-strand polypropylene [3] (commonly used on lobster pots and other fishing traps).

Best cutting technique: A wavy serrated blade drawn repeatedly through a loop.

Best tool for the job: Using a loop cut, the wavy serrated edges of the Spyderco Caspian2 Salt and UK Remora Ti did the job the fastest. However, the sharp plain edges of the UK Blue Tang Ti and Tusa FK-850 were the champs at flat sawing.

The material: 1/2-inch three-strand nylon anchor line. [4]

Best cutting technique: Wavy-style serrated blades cut through a loop with ease.

Best tool for the job: Spyderco Caspian2 Salt and UK Remora Ti led the pack. The serrated edges on the UK Blue Tang Ti and Tusa FK-850 also performed well, but their plain edges were even better using both the loop cut and flat saw cutting methods.

The material: 5/16-inch Vectran single-braid marine line. [5]

Best way to cut it: This is some really tough stuff. Most blades had trouble getting through it. Overall, repeatedly swiping a blade through a loop was the most effective method.

Best tool for the job: The Tusa FK-850 was the clear champ at cutting this material--both its long plain edge and wavy serrated edge worked well. The Spyderco Pacific Salt's plain edge was a close second.

Clean Cuts: Dive Knife Maintenance Tips

While the knives in this review remained mostly rust-free even after 15 days of wet neglect, our rust test is really no way to treat your dive knife. A little post-dive maintenance will help keep your blade shiny, sharp and ready to cut.

Rinse it. Remove the blade from its sheath and soak both parts in fresh water. If the knife disassembles that's even better, as it will allow you to clean all components separately, eliminating all those joints where corrosion loves to hide.

Wipe it down. After a good soak, give both sheath and knife a good shake, then wipe down the knife with a dry towel. This is when you want to inspect the knife closely for any signs of corrosion. A good rub with the towel will clean any rust spots before they get worse. Now's also the time to give your sheath's straps a quick look. Better to replace a dry-rotted strap now than to have it snap on you at 80 feet.

Spray it. Once dry, you may want to spray a light coat of silicone on the blade. You can get this stuff at virtually any dive store--it's also used on zippers. Then slide it back into the dry sheath. Do not use WD40 or any other petroleum products.

March 2007

By John Brumm

Photograph by Joseph Byrd

|| |---|

|

|

The new breed of dive knives tends to be smaller, which makes them easier to mount and stow; they have innovative blade designs which make them better suited to their true task of cutting through rope and fishing line (not throats and air hoses); and they're made of rust- and corrosion-resistant metals so they last longer and hold an edge better.

Making the Cut

The 11 models profiled here range from small emergency folding knives you can stash in a BC pocket, to traditional fixed-blade knives designed to be worn on a webbed belt or, if you're a traditionalist, strapped to your leg.

We put them all to the test to see how well they cut a variety of materials. Then we subjected them to our "rust test," an extended period of wet neglect in a saltwater environment to see how well they resist rust and corrosion.

For the cutting tests, we tried each blade in out-of-the-box condition on five different materials that today's divers are likely to face: 30-pound monofilament fishing line; 1/8-inch general-purpose Dacron line; 3/8-inch polypropylene line; 1/2-inch three-strand nylon anchor line; and 5/16-inch Vectran--a single-braid, low-stretch marine line so tough that it's used as a substitute for wire rigging. We discovered that the cutting efficiency of each knife depends largely on what's being cut. When attacking monofilament and Dacron line, virtually all knives get the job done. It's when you start sawing into the larger three-strand ropes and braids that you start seeing how different blade designs--not to mention cutting techniques--come into play (see: "The Cutting Test").

We tested for rust resistance by soaking the knives in salt water twice a day for 15 consecutive days. After each dunking, the knives were set out to dry while still in their sheaths. To our surprise, none of these knives showed much rust or corrosion at all. Most rust that appeared could be wiped off with a freshwater rinse and a brisk rubdown with a terry cloth towel. In spots where rust persisted, some light scraping with a razor blade took care of the problem. This clearly illustrates that any of these knives can be kept totally rust- and corrosion-free with just a little TLC (see: "Clean Cuts: Dive Knife Maintenance Tips").

Fixed Knives

OMS: Ti Knife

||| |---|---|

|<

table>

|

SCUBAPRO: Mako

||| |---|---|

|<

table>

|

SPYDERCO: Caspian2 Salt

||| |---|---|

|<

table>

|

TUSA: FK-850 X-Pert

||| |---|---|

|<

table>

|

UNDERWATER KINETICS: Remora Ti

||| |---|---|

|<

table>

|

UNDERWATER KINETICS: Blue Tang Ti Drop Point

||| |---|---|

|<

table>

|

XS SCUBA: Fogcutter X Recon Knife

||| |---|---|

|<

table>

|

Folding Knives

SPYDERCO: Salt 1 (yellow) & Tasman Salt (black)

||| |---|---|

|<

table>

|

Where the two knives differ is in the shape of their serrated edges. The Salt I has more of a convex cutting edge, while the Tasman Salt uses a curved "Hawkbill" blade. The Salt 1 blade is effective at both loop cuts and sawing against relatively flat surfaces. The Tasman blade has too much curve for standard sawing on flat surfaces, but excels in loop cuts.

SPYDERCO: Pacific Salt (black) & Atlantic Salt (yellow)

||| |---|---|

|<

table>

|

What To Look For In A Dive Knife

|| |---|

|

|

A serrated edge (top) is great for sawing-type cuts. Some serrated edges are pointy with sharp angles, others have a more wavy shape to their serrations. Wavy serrations (bottom) tend to cut material like heavy three-strand line more efficiently because the more rounded teeth run smoothly over the fibers, while the more pointy teeth have a tendency to get snagged.

Some blades offer both a serrated and a plain edge on the same cutting plane. Other knives separate their cutting edges; for example, the top edge is serrated, the lower edge is plain. This is a more functional design, because each edge type runs the entire length of the blade, thereby maximizing your cutting action.

Many blades also include a line-cutting notch (A). These are handy for snapping fishing line. However, a good plain or serrated edge will take care of monofilament just as efficiently.

|| |---|

|

|

The blunt tip (D) prevents you from accidentally stabbing yourself when returning the blade to its sheath. It also lets you use the knife as a pry tool without worrying about breaking the tip.

Pointed tips (B)--from stiletto to drop point styles--are not so good for prying, but they can make the difference between success and failure when you have to get a cut started by stabbing into a nasty rope knot. But be careful with a pointed tip; you can jab yourself or your BC bladder if you don't pay attention when sheathing it.

A tanto tip (C) is a bit of a hybrid. It's blunt, but with about a 70-degree angle to it and a sharp edge, similar to the edge on a chisel. You can do a little prying with less chance of snapping the tip, yet you also have that additional sharp edge if you need to do some cutting in tight spaces.

Blade Material. Most dive knives, and all knives in this review, feature blades made of either 304, 420 or H1 stainless steel, or titanium.

Softer 304 stainless steel offers excellent corrosion resistance, but it doesn't hold an edge as well as, say, 420 stainless, which does hold a sharp edge but rusts faster. H1 stainless is a special composite exclusive to Spyderco knives. It uses nitrogen in place of carbon in its steel matrix, resulting in a blade that's high in corrosion resistance while still being able to hold a very sharp edge.

And then there's titanium, the Superman of blade materials. It's harder than stainless yet lighter. You won't find better corrosion resistance, and the blade will hold a sharp edge for a long, long time.

A Good Handle. Regardless of the size of the knife, you want as much handle as possible to enable you to maintain a secure grip and full control of the blade. Good handles have textured surfaces or use special nonskid composites to provide a no-slip grip.

|| |---|

|

|

A Place for a Lanyard. (bottom) Underwater, wearing gloves, in a stressful situation it's just too easy to drop the knife. Handles that feature a hole at their base for stringing a lanyard will radically increase the chances of the knife staying with you.

A Good Sheath with multiple mounting options. Where do you want to mount your knife? Some of the larger models come with double straps for lashing to your leg, just like in the old days. But sometimes you want to thread it onto your weightbelt or some other length of webbing. Some sheaths come set up to do this. Others can be modified for web threading. Still others come with accessories that let you mount the sheath on a console hose or a BC pocket flap.

A sheath should enable you to release and draw your knife with one hand. Also, when you return the knife to the sheath, it should engage positively with a "click," ensuring the knife stays where it belongs.

Folding Knives

Folding knives are handy because they don't require a sheath, and they stow easily, either in a BC pocket or on a belt via a flexible clip. Like fixed-blade knives, folding knives should have textured grips so that they're easy to hold onto, and places for attaching a lanyard. Finally, a good folding knife lets you deploy the blade using one hand. It will also lock in the open position so the blade can't collapse on your fingers.

The Cutting Test

|| |---|

|

|

Loop Cut. After forming a loop with the line, we held the base of the loop in one hand, while with the other we took the knife blade and attacked the loop using an upward cutting motion.

Saw Cut. A length of line was stretched over a block of wood. Laying each knife edge on the line, we used a sawing motion to sever the line.

Here are the results.

The Material: 30-pound monofilament fishing line. [1]

Best cutting technique: Use a line-cutting notch or plain edge. Hook the line in the notch or along the plain edge, apply some tension, then give it a quick snap.

Best tool for the job: All knives in this group worked equally well.

The Material: 1/8-inch general-purpose Dacron line. [2]

Best cutting technique: A single swipe of a sharp plain edge through a loop works best.

Best tool for the job: All knives in this review worked equally well.

The Material: 3/8-inch three-strand polypropylene [3] (commonly used on lobster pots and other fishing traps).

Best cutting technique: A wavy serrated blade drawn repeatedly through a loop.

Best tool for the job: Using a loop cut, the wavy serrated edges of the Spyderco Caspian2 Salt and UK Remora Ti did the job the fastest. However, the sharp plain edges of the UK Blue Tang Ti and Tusa FK-850 were the champs at flat sawing.

The material: 1/2-inch three-strand nylon anchor line. [4]

Best cutting technique: Wavy-style serrated blades cut through a loop with ease.

Best tool for the job: Spyderco Caspian2 Salt and UK Remora Ti led the pack. The serrated edges on the UK Blue Tang Ti and Tusa FK-850 also performed well, but their plain edges were even better using both the loop cut and flat saw cutting methods.

The material: 5/16-inch Vectran single-braid marine line. [5]

Best way to cut it: This is some really tough stuff. Most blades had trouble getting through it. Overall, repeatedly swiping a blade through a loop was the most effective method.

Best tool for the job: The Tusa FK-850 was the clear champ at cutting this material--both its long plain edge and wavy serrated edge worked well. The Spyderco Pacific Salt's plain edge was a close second.

Clean Cuts: Dive Knife Maintenance Tips

While the knives in this review remained mostly rust-free even after 15 days of wet neglect, our rust test is really no way to treat your dive knife. A little post-dive maintenance will help keep your blade shiny, sharp and ready to cut.

Rinse it. Remove the blade from its sheath and soak both parts in fresh water. If the knife disassembles that's even better, as it will allow you to clean all components separately, eliminating all those joints where corrosion loves to hide.

Wipe it down. After a good soak, give both sheath and knife a good shake, then wipe down the knife with a dry towel. This is when you want to inspect the knife closely for any signs of corrosion. A good rub with the towel will clean any rust spots before they get worse. Now's also the time to give your sheath's straps a quick look. Better to replace a dry-rotted strap now than to have it snap on you at 80 feet.

Spray it. Once dry, you may want to spray a light coat of silicone on the blade. You can get this stuff at virtually any dive store--it's also used on zippers. Then slide it back into the dry sheath. Do not use WD40 or any other petroleum products.